The Benefits of Collaborating with Micro-Tronics on Part Design

Leave a CommentThe Benefits of Collaborating with Micro-Tronics on Part Design

In precision machining, the road to success begins with part design.

Every engineering blueprint, including every specification and tolerance, must be carefully considered to ensure optimal and efficient production of parts. However, even the most well-optimized designs can benefit from input from manufacturers.

It’s not that we can’t meet challenging requirements. With advanced in-house capabilities like wire EDM, we can do just about anything. But if time and cost savings are your goal, we’ve found that 20% of the prints we receive could benefit from time and cost-saving design improvements. In one case, we provided design recommendations that had the potential to reduce a customer’s cost and lead time by an incredible 75%!

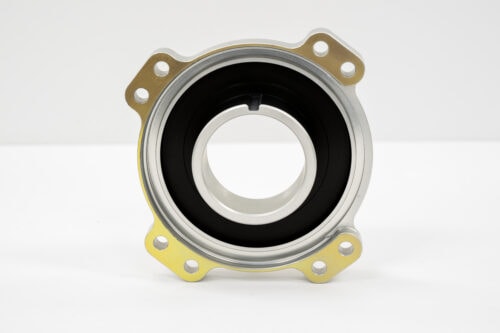

When customers work with us to fine-tune a design, they benefit from a smooth manufacturing process and the quality Micro-Tronics is known for.

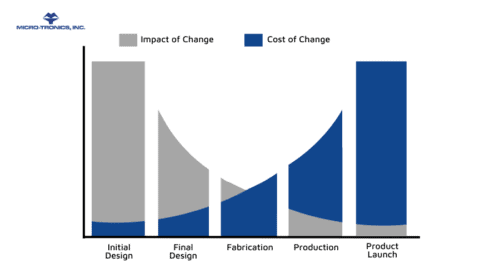

The Benefits of Early Engagement with Your Precision Machining Partner

Knowledge transfer is a crucial aspect of early engagement. Design engineers and manufacturers can exchange ideas and share expertise, leading to a more collaborative and informed approach to precision machining.

Engaging with Micro-Tronics in the design phase offers two main advantages:

- Optimized designs that are faster and more cost-effective to manufacture

- Insights about new materials, technologies, or manufacturing methods

When customers take advantage of early engagement, they can avoid issues like missed deadlines and budget overruns.

The Importance of Partnership in Precision Machining

At Micro-Tronics, we believe in forming true partnerships with our customers. Our approach goes beyond building a transactional relationship—instead, we actively engage in detailed discussions with our customers to address potential challenges related to tolerances, material specifications, preferred suppliers, and more.

This level of collaboration accelerates the manufacturing process and eliminates common errors, assuring the optimal and efficient production of parts.

Customers who actively participate in the design process with us typically achieve a more streamlined production experience and receive higher-quality parts delivered in a cost-effective manner.

How Micro-Tronics Saves Customers Money

When collaborating with Micro-Tronics on part design, there are two common areas where costs can be reduced.

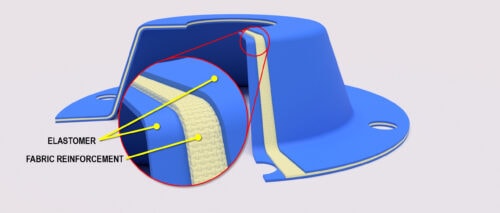

Adjusting things like tolerances can have a significant impact on both time and cost savings. By identifying areas where tolerances can be optimized without compromising the integrity of the final product, Micro-Tronics can produce parts more efficiently and cost-effectively.

Micro-Tronics’ Collaborative Process

Our team excels at manufacturing parts, but we aren’t design engineering experts. The best results occur when customers design the part and then consult with us to ensure that the part is manufacturable. This approach leverages the strengths of both parties and results in a seamless transition from design to manufacturing.

Our commitment to true partnerships and active collaboration sets the stage for manufacturing success that goes beyond mere execution, ensuring every component’s design is optimized for the highest quality and efficiency.

Request a quote today.