Molding Fluorosilicone Grommets and Interfacial Seals for Aerospace and Beyond

As experts in custom elastomer molding, we have extensive experience working with a vast array of rubber molding materials. Our premium capabilities are crucial for aerospace parts, which often have complex features and require exceptional environmental properties.

Want a prime example of how Micro-Tronics leverages custom molds, premium materials, and proprietary techniques to craft critical elastomer products to perfection? Look no further than the aerospace-bound electrical connectors we regularly manufacture.

Grommets and Interfacial Seals for Electrical Connectors

Electrical connectors—electromechanical devices that join electronic circuits—need insulators to prevent unwanted conductivity. Grommets and interfacial seals, custom-molded from rubber, provide necessary insulation for wires and pins.

Choosing a high-performing material for high above the Earth

Many industries incorporate elastomer insulators into their electrical connectors, but the most stringent insulation requirements are found in assemblies destined for aerospace applications. To achieve the mission-focused (and possibly life-preserving) potential of aerospace parts, Micro-Tronics custom molds the necessary grommets and interfacial seals out of fluorosilicone.

Fluorosilicone and silicone have similar stability and compression set resistance in extreme temperatures. However, fluorosilicone uniquely embodies trifluoropropyl groups that provide enhanced chemical resistance.

The long-lasting elastomer boasts outstanding heat resistance and thermal properties, with a standard service temperature range of -80° to 400° Fahrenheit and a brittle point of -85° Fahrenheit. Though fluorosilicone’s flame resistance isn’t exceptionally high, its other environmental resistance qualities are impressive, as is the material’s fluid resistance (with the exception of polar solvents).

Fluorosilicone’s superior properties make it today’s gold standard for elastomer products. And at 5x the price of regular silicone, the material’s proverbial middle name may as well be “gold.” Outside the high-risk aerospace industry, insulative materials such as silicone, black rubber, neoprene, and other elastomers are viable, cost-effective alternatives.

Mold-making for fluorosilicone grommets and interfacial seals

Before making fluorosilicone grommets and interfacial seals, Micro-Tronics must make molds for both parts.

Generally, this step isn’t overly complicated. However, making molds for these particular grommets and interfacial seals is deceptively challenging due to the dense population of tiny pins that are needed to form these parts. It can get quite crammed in the mold with all those little features!

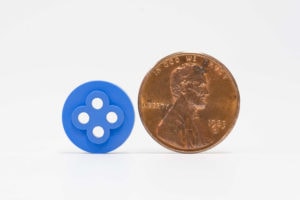

Done correctly, the resulting mold’s pin and wire holes feature complex inner geometries, ensuring minuscule ridges for guiding the pins into place and tight seals around the pin exit points. Both grommets and seals must hold critical tolerances to ensure the closely adjacent pins don’t dislodge from their target placements.

It’s not uncommon for an electrical connector to comprise 100 pins within a one-inch diameter assembly space. Some connectors hold pins with unusual dimensions, such as hourglass shapes, further elevating their complexity.

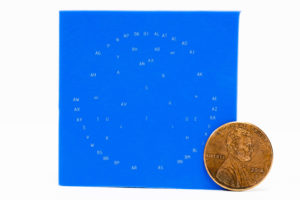

Proprietary part marking for elastomer products

Micro-Tronics appreciates the value of part marking for inventory and ordering purposes. But part marking is uniquely important when assemblers must accurately thread dozens of miniature pins and pin wires through specifically assigned holes.

Using a proprietary laser marking process, Micro-Tronics lifts microscopic black or white markings to the surface of each grommet and interfacial seal. This ink-free process creates zero waste while establishing permanent marks that will not wear away and are solvent-resistant.

Trust Micro-Tronics for Your High-Precision Rubber Components

When you need custom precision parts, Micro-Tronics can make rubber molds and products to even the most exacting specifications. Whether your components call for rubber injection, compression, or transfer molding, our team will meticulously craft your elastomer products using the appropriate AMS, ASTM, MIL, and FDA-certified material.

Request a quote to begin your next rubber molding project with us!