How to Leverage EDM Technology for High-Tech Electromagnetic Parts

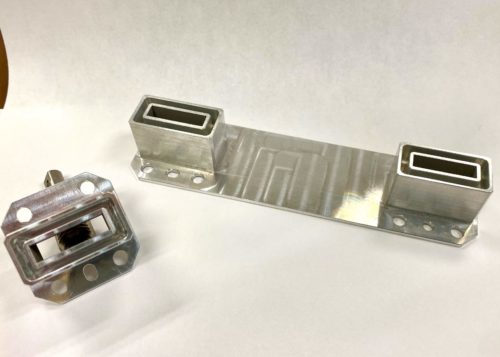

What do waveguides, septum polarizers, comparators, wide beam feeds, septum polarizer housings, feed horns, socket end waveguide gimbal feeds, chokes, and flanges all have in common?

Each of these radio frequency (RF) communication parts has internal right angles—and the only way to accurately achieve these features is with EDM manufacturing—electrical discharge machining.

Let’s explore why EDM is the best solution for machining high-tech electromagnetic (EM) parts and how Micro-Tronics leverages EDM technology to achieve exceptional precision.

Need Perfect Square Corners? EDM Manufacturing Is the Answer

External right angles are easy enough to machine with a lathe or mill. Internal right angles, however, cannot be achieved with conventional machining. Lathes and mills will always leave small radii, channel tags, or earmarks anywhere square corners are attempted.

So what do you do when your part’s interior requires precise right angles? Radio frequency communication parts, for example, won’t function without internal right angles to bounce radio waves through the part’s channels.

EDM services are the perfect solution for machining square corners and tight tolerances.

Achieve Incredible Precision with Wire EDM and Sinker EDM

As long as your part is made of a conductive material, Micro-Tronics can use EDM to precisely shape your workpiece. Our expert team performs two styles of EDM manufacturing:

Wire EDM

Highly accurate and ideal for carving complex geometries and precision components, wire EDM smoothly cuts through an entire workpiece using electricity that is sent to the workpiece via a spooled brass or copper wire as it unwinds along the substrate.

Sinker EDM

Also called “plunge EDM,” this process can be used to create very intricate shapes (typically blind holes) with incredible precision and accuracy. Using a conductive ram electrode (typically made of copper or graphite), sinker EDM can imprint highly accurate features of varying depths. We frequently utilize sinker EDM manufacturing when making aerospace, automotive, energy, manufacturing, medical, and military and defense components.

Our EDM setups

Micro-Tronics maintains multiple EDM setups ready to work at a moment’s notice. On our shop floor, you’ll find:

- 25 sinker EDM machines

- 14 wire EDM machines

- 6 fast hole EDM machines

EDM-compatible materials

Because EDM manufacturing cuts via the electrical discharge between two electrodes (one of which is the part itself), the workpiece’s substrate material must be electrically conductive. EDM’s erosion power allows us to cut even extremely hard, difficult-to-machine metals, such as Inconel. Here’s a list of materials that are compatible with EDM:

- Aluminum

- Carbide

- Cobalt

- Hastelloy

- Inconel

- Rhenium

- Stainless steel

- Tool steel

- Titanium

- Any other conductive material!

With CNC-guided EDM manufacturing, we can clean-cut your components with exceptional accuracy and a smooth surface finish.

The Advantages of Combining EDM Services with CNC Machining

Many parts require both CNC machining and EDM services, and it pays to work with a shop that offers both capabilities under one roof.

Micro-Tronics is your one-stop shop for CNC machining and EDM manufacturing

With our combined CNC machining and EDM capabilities, you’ll save time and money: simply submit a single purchase order, and you can expect to receive finished parts made entirely by our team.

No more shipping your parts around to different vendors for individual services or having your vendor sub out the EDM work leading to more cost and lead time. Micro-Tronics can create even the most complex features and geometries in-house, ensuring consistent quality, sharp interior corners, and smooth surface finishes.

And because Micro-Tronics has over 50 years of experience machining and EDM’ing intricate parts just like the ones mentioned below, your order will always be expertly machined and delivered on time with the utmost care.

We’re proud to make EM and RF components that serve an array of industries and individuals via myriad applications, such as:

- Waveguides

- Septum polarizers

- Comparators

- Wide beam feeds

- Septum polarizer housings

- Feed horns

- Socket end waveguide

- Gimbal feeds

- Chokes

- Flanges

Ask for CNC Machining + EDM Services at Micro-Tronics

If you’re looking for a manufacturing partner for your high-tech radio frequency and electromagnetic parts, Micro-Tronics has the equipment, experience, and expertise you need.