Our Bonded Plate Seal Capabilities

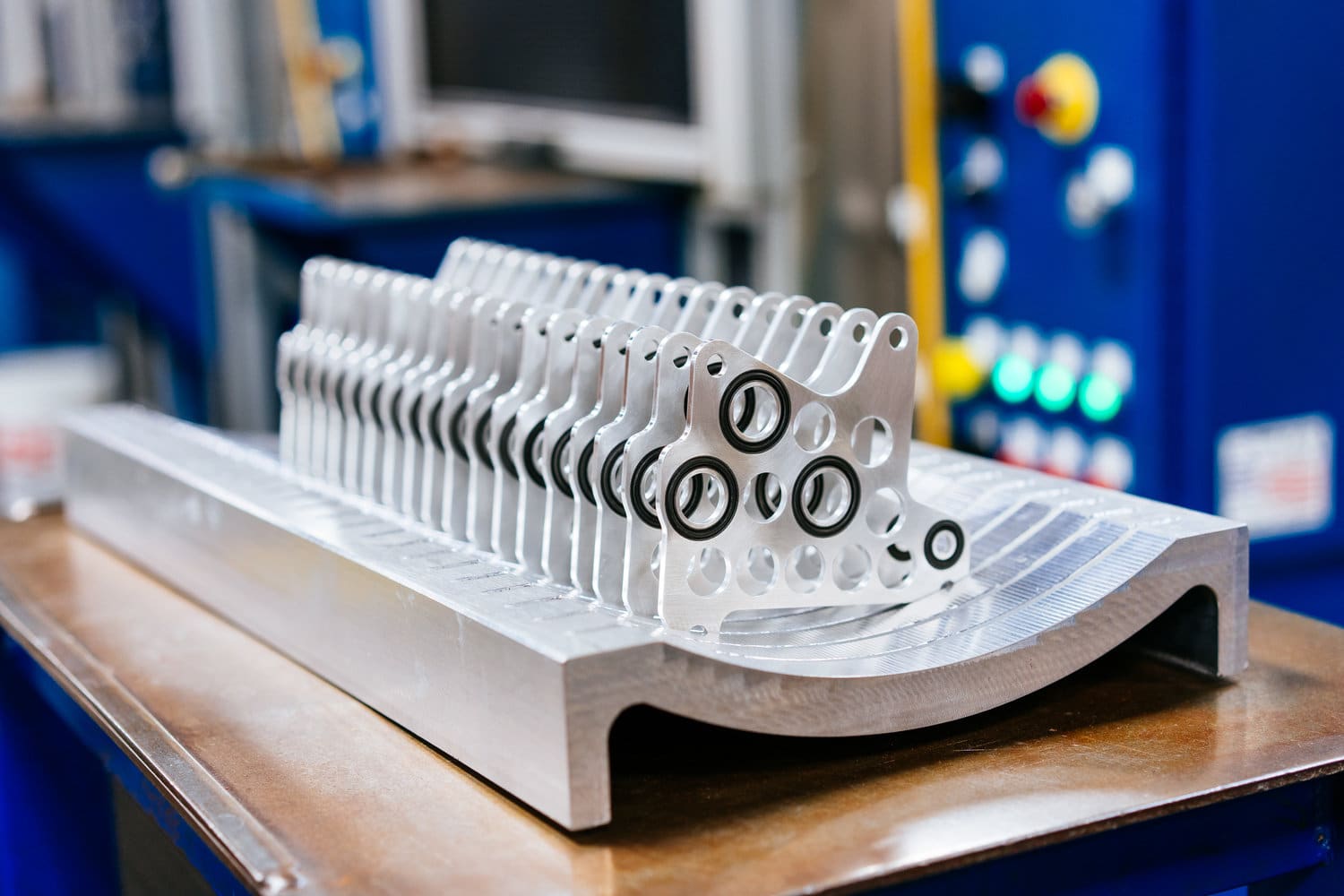

The team at MTI offers turnkey solutions for our customers; our in-house machine shop and full scope of services reduces lead time for our customers’ components, prevents handling issues, and allows us to hold tighter flatness tolerances.

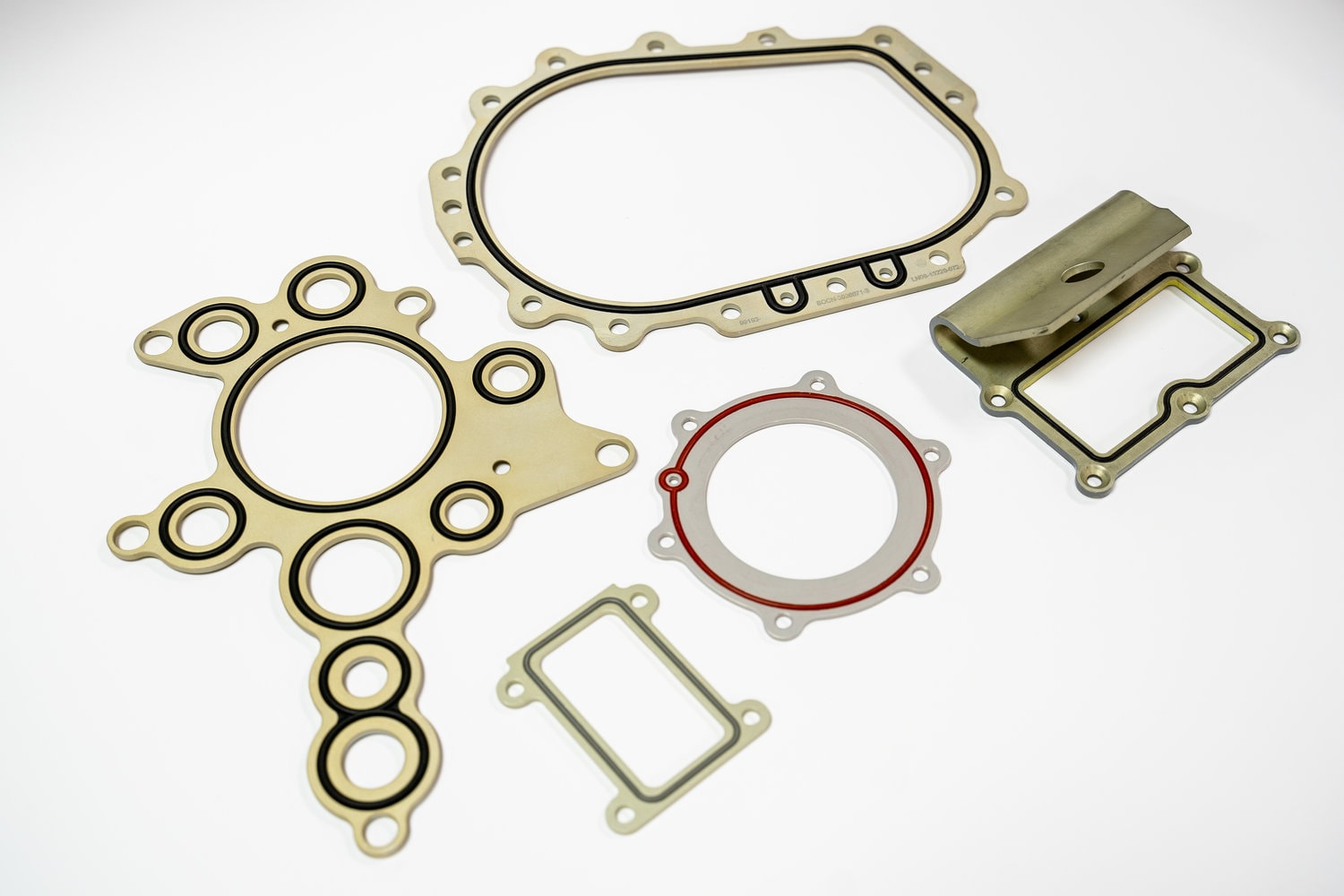

We offer rubber-to-metal bonding services for components in a variety of shapes and sizes. We can create seal plates, valves, and other metal components with seal beads as well as vibration isolators, gaskets, and other fully or partially encapsulated components. We can also mold solid elastomer parts and products, such as boots, bumpers, isolators, grommets, and more. We can also repurpose pre-existing plates; we can remove old elastomers and adhesive from the plates and replace them with new rubber and adhesive.

Our facility houses rubber molding equipment with pressure capacities ranging from 30 to 400 tons and platen sizes up to 24 inches by 24 inches. While the work envelope depends on the configuration of the part or product, the equipment has the capabilities to process most elastomer components. As a result, we can create bonded seals suitable for closing fluid systems used in virtually any industry or application.

Our application engineering team can work with your pre-existing or conceptual designs to ensure they are designed for manufacturing. This assistance can include confirming the right manufacturing processes, tooling, and materials for your components. We can also assist with choosing the right adhesive and process for bonding your desired elastomers and metal components.

Get in touch with us →

Bonded Plate Seal Materials

Both the metal ring component and the rubber component of bonded seals can be made from a variety of materials to suit different sealing applications. For example, the ring can be made from aluminum, brass, or stainless steel, while the elastomer seal can be made from EPDM, nitrile, silicone, or Viton. We can also accommodate non-metallic plates, such as plastic substrates.

At MTI, we can utilize our proprietary rubber formulations and many of these formulations meet AMS, MIL and NSF specifications. These formulations can consist of combinations of the following materials:

- Silicone

- Nitrile

- EPDM

- Fluorocarbon aka Viton

- Fluorosilicone

- Neoprene

- Kapton

Why Partner With MTI for Rubber-to-Metal Bonded Seals?

Need rubber-to-metal bonded seals for your next project? MTI has got you covered. We offer a range of in-house services to our customers, including metal and rubber manufacturing, bonding, and product assembly, which allows us to cut weeks to months off startup lead times.

- Our application engineering team can ensure your designs are prepared and well-suited for manufacturing.

- Our machine shop enables us to machine the metal components (e.g., metal rings and plates) required for our rubber-to-metal bonding operations.

- Our tool room enables us to design and build our molds and finish dies.

- Our rubber formulation capabilities enable us to make standard or custom materials as needed.

- Our assembly shop enables us to mate and assemble other components to our molded rubber products to create larger subassemblies as well as kit our molded rubber products with other assembly line components.

- Our value-added services enable us to accommodate laser marking, bag and tag, stock programs. and other final packaging needs.

Molded Rubber Products from Micro-Tronics, Inc.

Bonded seals play a vital role in fluid systems. That’s why it is essential to choose the right ones for your particular application and source them from a reliable supplier.

At Micro-Tronics, we have the experience, equipment, and expertise to deliver bonded seals for many different industries and applications. We can tailor them to meet your exact specifications and standards, including AMS, MIL, SAE, and ASTM. Our AS9100D- and ISO 9001:2015-certified quality management system ensures you receive the highest quality solution. Our NADCAP certification denotes our outstanding quality and commitment to precision molded products.

To learn more about our rubber-to-metal bonded seals and how they can benefit your equipment, contact us today. To discuss your bonded seal needs with one of our experts, request a quote.