Custom Rubber Molding Services

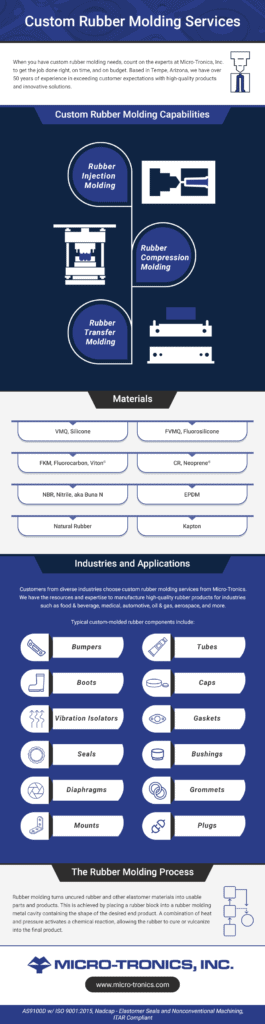

When you have custom rubber molding needs, count on the experts at Micro-Tronics, Inc. to get the job done right, on time, and on budget. Based in Tempe, Arizona, we have over 50 years of experience in exceeding customer expectations with high-quality products and innovative solutions.

As an industry-leading manufacturer of precision rubber components, we have the experience, industry certifications, and state-of-the-art equipment to find a unique solution to almost any design or rubber molding challenge. Our custom molding capabilities, combined with the ability to work with various rubber molding materials, enable us to manufacture American-made solutions to your unique specifications.

Our Custom Rubber Molding Capabilities

When standard components don’t meet your needs, Micro-Tronics offers custom rubber molding capabilities to create rubber products that meet your specifications. Our design team works with you to understand your exact requirements to determine the best solution for your application.

Our custom rubber molding capabilities include:

- Rubber Injection Molding. This process is best for parts that require high volumes, tight tolerances, over-molding, or high levels of precision. It is highly efficient and ideal for rubber to metal bonding.

- Rubber Compression Molding. We recommend this process for low to medium production volumes. This method allows for the cost-effective production of large and intricate parts that require a longer curing time. It also features lower tooling costs compared to rubber injection molding.

- Rubber Transfer Molding. Here, the material is compressed by a plunger and transferred through runner and sprue channels into the forming cavity. The plunger remains in place until the rubber takes on the desired shape and the product has finished curing or vulcanizing. This process offers tighter dimensional tolerances than compression molding and allows for rubber over-molding or rubber to metal bonding.

Materials

Our team will work with you to determine the best possible material for your custom rubber molding project. We have many materials which meet AMS, ASTM, MIL, and FDA requirements. Our material options include:

- VMQ, Silicone

- FVMQ, Fluorosilicone

- FKM, Fluorocarbon, Viton®

- CR, Neoprene®

- NBR, Nitrile, aka Buna N

- EPDM

- Natural rubber

- Kapton

Industries and Applications

Customers from diverse industries choose custom rubber molding services from Micro-Tronics. We have the resources and expertise to manufacture high-quality rubber products for industries such as food & beverage, medical, automotive, oil & gas, aerospace, and more.

Typical custom-molded rubber components include:

- Bumpers

- Tubes

- Boots

- Caps

- Vibration Isolators

- Gaskets

- Seals

- Bushings

- Diaphragms

- Grommets

- Mounts

- Plugs

The Rubber Molding Process

Rubber molding turns uncured rubber and other elastomer materials into usable parts and products. This is achieved by placing a rubber block into a rubber molding metal cavity containing the shape of the desired end product. A combination of heat and pressure activates a chemical reaction, allowing the rubber to cure or vulcanize into the final product. Although there are various ways to perform the rubber molding process, they all rely on heat and pressure to form rubber products.

To learn more about the Rubber Molding process, view our blog article on the topic here.

Partner with Micro-Tronics for Custom Rubber Molding Services

At Micro-Tronics, our custom rubber molding capabilities and value-added services allow us to deliver top-quality rubber products for customers across a diverse range of industries. With an extensive selection of materials and equipment, our expert team can provide custom solutions tailored to your exact needs. To learn more about rubber molding, check out our Complete Rubber Molding Guide. You can also contact us today or request a quote to get started on your next custom rubber molding project.