Choose Micro-Tronics for Deep Draw Diaphragm Molding

Although most rubber product manufacturers mold flat or even shallow elastomer diaphragms, Micro-Tronics is one of an elite few with the expertise to make a more complex variation of this common part: the deep draw diaphragm.

Our cutting-edge, proprietary technique for molding these specialty elastomer diaphragms enables us to manufacture them repeatedly and consistently for mission-critical applications.

What Is a Deep Draw Diaphragm?

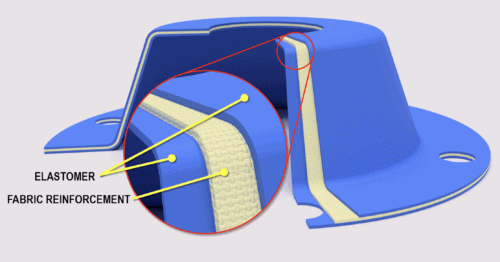

A deep draw diaphragm is a fabric-reinforced diaphragm with a high aspect ratio where the height can be greater than the diameter. These strong and flexible rubber seals typically have adepth greater than 0.5” and feature up to a 90-degree angle, lending them the shape of a top hat. Like all diaphragms, they are used to seal off the contents of one component from another.

These parts are also known as rolling diaphragms because they move up and down and are used to separate different fluid or gas environments, or to transmit pressure from one side of the membrane to the other. They work in concert with other assembly components, such as backing plates, springs, and cups.

Common Deep Draw Diaphragm Applications

A wide range of industries rely on deep draw diaphragms to ensure the safety and performance of their parts:

- Aerospace

- Agriculture

- Oil and gas

- Water treatment

- Medical

- Heavy Industrial

Deep draw diaphragms are used to control pressure and ensure the proper transfer of liquid and air among the chambers of parts, including:

- Hydraulic control and relief valves

- Meters

- Pumps

- Pneumatic control valves

- Regulators

- Other control devices

What Makes Deep Draw Diaphragms So Challenging to Mold?

The internal fabric reinforcement that makes deep draw diaphragms so durable also makes them tricky to manufacture. Unfortunately, the process isn’t as simple as placing rubber and fabric together in a mold and pressing the mold closed. Correctly manufacturing the cloth requires incredible precision. The ultimate goal is to prevent wrinkles and tears and ensure proper bonding between rubber and fabric.

If the fabric weave is misaligned or deformed in any way, it can cause the part to fail. Most concerning, fabric separation in the diaphragm can create a pressure bleed, leading to a potentially catastrophic blowout.

Additionally, small defects in the fabric may create weak points that go unnoticed over time, gradually forming small holes in the rubber. As these cracks propagate, the diaphragm will degrade prematurely, potentially compromising the entire control unit on which it is mounted.

When you work with Micro-Tronics, you can be confident that we’ve honed our processes to overcome the manufacturing challenges associated with molding deep draw diaphragms. We leverage our years of expertise to create deep draw diaphragms that meet our customers’ specifications, using a proprietary technique that delivers consistently excellent results.

Using Elastomers to Create Deep Draw Diaphragms

Elastomer diaphragms are typically made of materials like silicone, flourosilicone, nitrile, neoprene, EPDM, FKM, or other polymers that have the ability to flex and recover their shape when subjected to pressure. These materials are chosen for their durability and flexibility, as well as their resistance to chemicals and other environmental factors.

The part’s end-use application will determine which elastomer is best for your deep draw diaphragm. For instance, only certain elastomer types are capable of withstanding extreme temperatures or resisting a particular fluid.

Silicone and Nomex® are popular for aerospace applications due to their ability to endure extreme heat and cold. For oil and gas applications, choose oil-resistant nitrile or neoprene.

Count on Micro-Tronics for Deep Draw Diaphragm Molding

At Micro-Tronics, we mold 20 different elastomers, and we’ve even created a guide to help you determine which one is best for your rubber diaphragm. With our deep knowledge of elastomers and our proprietary technique for molding deep draw diaphragms, Micro-Tronics is the company you can rely on for flawless execution and performance.

To learn more, request a quote today!